Process Mining 101: Are you ready for process mining?

2022/2/2

Author: Chanisara Kajornchaikul

Table of Contents

Introduction

Hello, my name is Chanisara, Associate DX Consultant at ISOL. Today I’d like to introduce you to the concept of process mining. Over the past few decades, process mining has become the buzzword in the IT industry. If you have no idea about process mining, you may have several questions when you hear this word for the first time. For example,

- What is process mining?

- What are the benefits of process mining?

- Are there any use cases of process mining tools?

- Is it suitable for my business industry?

- How do I start with process mining?

Don’t worry! I’ve got your back. I‘ll guide you through process mining step by step. This article will cover the basic definition of process mining, as well as the benefits, and practical application. Then, conclude with how to get started with process mining.

Please trust me. Regardless of the industry field you are in, whether you’re in charge of process management or come from a different background, you’ll gain a better understanding of process mining after reading this article.

What is process mining?

Processes are the core of every business. Generally, order to cash and procure to pay processes are the standard business processes[3], however, in a company, there are much more specific processes. Process mining is an outstanding solution for understanding the business process among the tools to visualize and analyze the process.

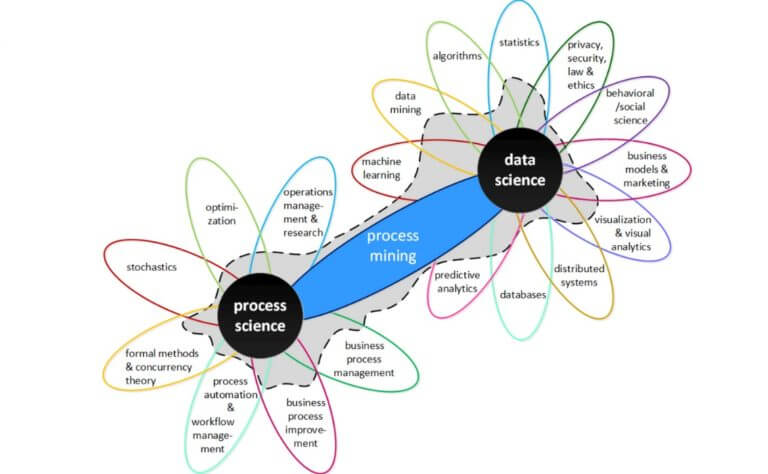

According to Wil van der Aalst, who is known as the godfather of process mining, process mining is the bridge between data science and process science[1]. These two sciences are totally different. Data science is the means of extracting meaningful insights from data, whereas process science is the end-to-end process modelling without any evidence-based data. By combining this knowledge, process mining is a hybrid of data-driven and process-centric.

There is another definition of process mining. According to the Gartner glossary, process mining is an approach for discovering, monitoring, and improving real processes through event logs from IT systems[2]. It includes many features such as automated process discovery, conformance checking, social network, simulation models, case prediction, etc.

Now that you’ve read about the basic concept of process mining, you may be wondering why your organization should employ it. Here are the 5 great benefits that your firm may enjoy while utilizing process mining.

The 5 great benefits of process mining

1. Transparency through the end-to-end process

When it comes to an organization’s operations, even if the process manual is distributed and all stakeholders follow it, in practice, particularly with complex processes, deviations often occur, and it may cause problems. It is difficult to resolve issues without identifying the root cause. Therefore, process mining is important in one’s organization. It can automatically create the process diagram by loading event logs. Then, with the insightful diagram process, you can discover deviations, prevent problems before happening, and easily standardize processes for the entire organization thanks to the transparency that process mining provides.

2. Cost saving and increased return of investment (ROI)

Because process mining can give transparent end-to-end processes, hence unknown inefficiencies and automation opportunities can be discovered. Imagine how great it would be if you could save money and increase your ROI by eliminating unnecessary activities and optimizing your operations.

3. Boost efficiency while minimizing risk

Through process mining, different KPIs and custom indicators can be set up into the process mining simulation to detect bottlenecks in your business processes. Consequently, issues such as inefficiency and risk can be controlled, if the source of the problem is identified.

Let’s take the automobile industry as an example. When the R&D department releases a new design, generally the whole organization will be affected. Back-and-forth communication between departments can cause many reworks leading to bottlenecks in the process. With the help of process mining, the pain point where there is a delay in cross-department workflow can be identified via simulation features, therefore, the solution plan can be implemented at the right place and time. For example, if the delay is caused by the lack of resources, optimization of resource allocation is a countermeasure that can be taken against the issue. To sum up, process mining can help you find the root cause of a problem, which in turn helps you to come up with the best solution.

4. Improve business resilience

Process mining is a small step that connects operational data to the more significant strategic initiative like digital transformation. More than just discovering new opportunities for digitization, process mining can also improve business resilience. Thanks to real-time process model analysis, problematic areas and corrective measures can be discovered in a short time. This is a great value of process mining as the world moves towards digitalization, there is an increased importance for operational resilience and adaptability, and when a crisis strikes, process mining will be a powerful tool to support business contingency planning (BCP). Process mining can ensure quick and smooth operations.

5. Enhancing customer satisfaction

Process mining gives you an insight to make the right decision in your business. Conventionally, when there is a problem with long lead times, in-depth interviews are often conducted to determine the root cause of the problem from the beginning to the end of the process. However, this is an inefficient practice because it requires a lot of time, may not reflect the real causes and in highly competitive markets, the company would risk losing an important customer. With the clear vision of the process provided by process mining, you can satisfy the customer in a shorter response time.

Even if, after reading about the advantages of process mining, you’re still not convinced, please keep reading. From here, we’ll go further into real-world process mining examples.

Use cases of process mining

Logistic industry[6]

Generally, shorter lead times are preferred in the logistics industry. With process mining, the group operations manager at Veco in the Netherlands, Joris Keizers, could characterize all operations within the company. He transferred data from the Enterprise Resource Planning (ERP) system to the process mining software of ‘Disco’ and he used the smart algorithm with 3 different parameters: first, the production order number to which it belonged, second the executed workstation places, and finally, the time when the operation began. As a result, Joris could identify which workstations always or never followed one another by the smart algorithm of process mining. It demonstrated how the process worked and whether it deviated from the original plan.

In addition, with process mining, Joris could also run a replay of a certain time period to check how the orders flowed through the factory, and if he found a delay in the process, he could filter which orders were affected. Contrary to a graph or statistics, process mining appealed to have much more impact. For example the required communication for corrective actions to pertaining teams was clearer , providing a wider range of solutions to aim for operational excellence. This is an example indicating that for warehouse managers, with an analytical background, learning process mining would be reasonably easy and quick.

Manufacturing industry[7]

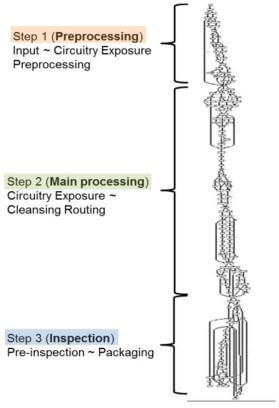

Conventionally, Samsung Electro-Mechanics (SEM) Co.,one of South Korea’s leading manufacturers, developed a MES (Manufacturing Execution System) to help their manufacturing department execute procedures and make better decisions. Even though SEM’s Equipment Optimization Technology (EOT) department applied statistics and data mining to analyze data from the MES, only a specific manufacturing task was well analyzed. EOT had struggled to provide the overall process-level analysis (e.g. overall performance, manufacturing patterns, etc.). Several questions were asked by the EOT department to UNIST, BPI lab as follows:

- What is an actual process flow in SEM?

- Are there any abnormal traces of a lot?

- Are there any bottleneck points in the process?

- How are the machines utilized?

Therefore, BPI lab proposed Prom, a process mining tool as a solution to analyze manufacturing processes.

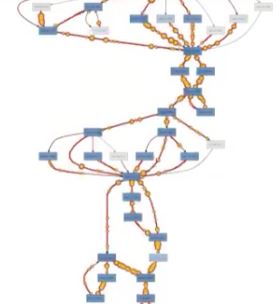

- Based on the manufacturing event logs from the MES in SEM, the following results were obtained after using process mining: The derived process model showed actual process flows in the factory as shown in the figure 3, providing better insight into the manufacturing process.

- The conformance checking shows the fitness value of the overall process to 0.9962 from 1( for 100% conformance) , indicating that the model from event log deviated from the ideal process. Although few abnormal flows were found from the Delivery Inspection task to the Final Test task, the high-value fitness close to 1 indicates that management of the manufacturing process in SEM is good.

- The machine performance analysis shows an imbalanced usage of 7 machines for the packaging task. Process mining found that N20031 has the longest working time, 90% of lots were completed within 5 hours for the package, but there were a few cases that took more than 1 day to complete.

In conclusion, managers of SEM were pleased with the process mining results. For their SEM monitoring and analysis, they planned to continue using process mining to improve their processes.

Apart from logistics and manufacturing, process mining has several potentials in other areas such as IT service management, the procure-to-pay process in financial industries, customer service, health care systems, and so on. As long as there are processes, process mining can be applied to any industry.

How to get started with Process mining

The most successful use of process mining is when it is applied to high-volume operations with a specific aim in mind. In order to reap the full benefits of the process mining, it is necessary to set your business goal and start collecting basic data required for process mining such as Case ID/Event ID, Activity, and Timestamps.

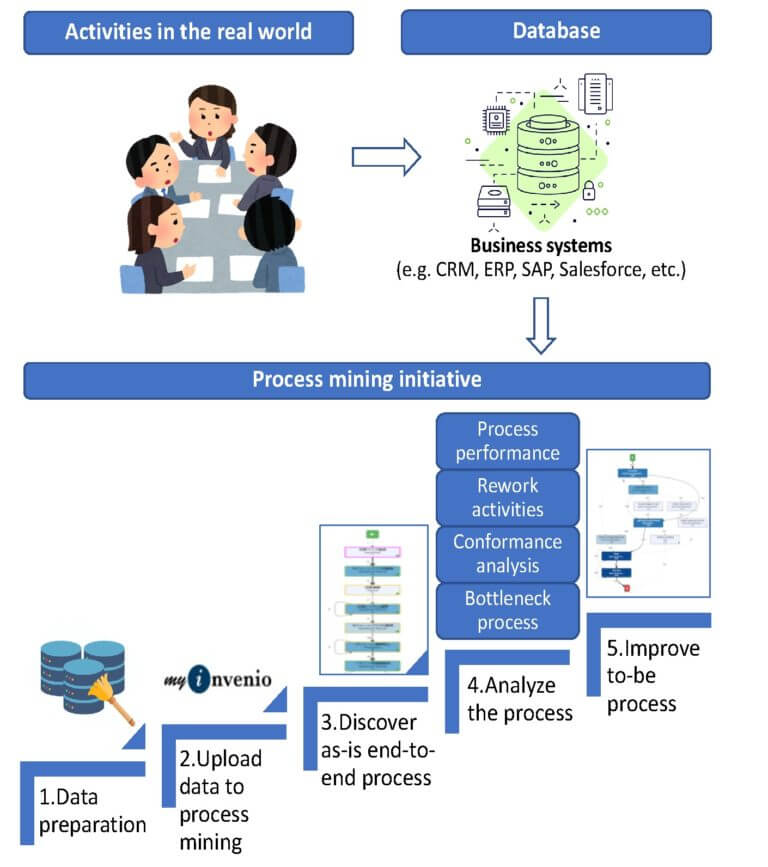

As shown below, the process mining initiative has 5 steps including;

- Data preparation,

- Upload data to process mining tool

- Discover the as-is end-to-end process

- Analyze the process

- Improve to-be process

At first, you may find it challenging to get started with a process mining project. However, process mining will make the rest of your journey to improve the business process much easier. Because without good data preparation, process mining can’t reflect your as-is process. Therefore, data preparation is the most important and the biggest step to start process mining. In order to get over that stepping stone, ISOL can be your best partner to support your journey.

If you have some concerns about process mining, please don’t hesitate to contact us. ISOL will help you understand process mining and achieve your business goal. We will always be here to support you to deliver value to your business. Also, if you’re here to learn more about process mining or ISOL’s solutions, please don’t hesitate to sign up your email here, we will keep you up to date with the latest information.

References

[1] W. van der Aalst, “Process Mining: Data Science in Action,” Springer Verlag, 2016.

[2] https://www.gartner.com/en/information-technology/glossary/process-mining

[3] https://pafnow.com/blog/process-mining-101-what-is-process-mining/?fbclid=IwAR2uuM5-WphU8eSEPoXrPzXkw5quSZviHsNZk05oqb9KSnRiuqkAaa07NmE

[4] https://www.signavio.com/post/how-process-mining-supports-operational-resilience/

[5] https://www.gartner.com/doc/reprints?id=1-285KIS1W&ct=211118&st=sb

[6] https://www.tf-pm.org/resources/casestudy/interview-with-the-logistics-manager-of-the-year

[7] https://www.tf-pm.org/resources/casestudy/process-mining-at-samsung-electro-mechanics